Transat - Repairs off the beaten track and another lesson learned - part 2

- Ana

- Apr 2, 2023

- 6 min read

After having our spirits crushed again when the autopilot blew the fuse after a couple of hours of use, we decided that, at this point, we had nothing to lose. The autopilot was indeed broken, maybe we could find out the exact part that was causing trouble, and who knows, maybe we could source that element individually (we learned a long time ago most items in the nautical world are common to other industries like swimming pools, car electrics and mechanics, etc.).

With the motto: "You cannot break what is already broken" (when something is broken and you cannot find a tech to fix it, nothing you do puts you in a worse situation than the one you are already in), we decided to start disassembling the Lewmar drive unit and see if we could either learn something and maybe find a way to fix it or clear once and for all the doubt if the pilot was dead and unrepairable.

Long ago, we grew tired of the current attitude of technicians that do not repair anything, just telling us that some needs to be replaced and is not repairable without even trying unless it is an easy or minor fix.

We opened the lazerette where the unit is installed and removed it. With the pilot unit now on the cockpit table, it was surprising to see how big it was, we had always seen it so up close and at awkward angles due to the size of the locker skewing our perspective.

Like busy bees, we started removing all the pieces not relevant to the actual functioning of the pilot before we shoved the main unit in a waterproof backpack, together with lots of tools and headed out to our friend's house, where we had access to good internet.

Despite being in Brazil for nearly a month and after having successfully managed to buy a SIM card (link to Brazil formalities), we were still struggling with the internet services.

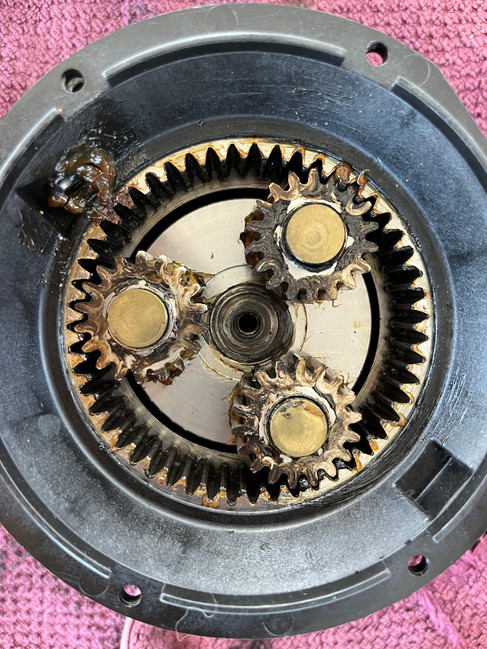

At our friend's house, we found a few videos on the internet showing different versions of our autopilot being disassembled, and although it wasn’t exactly the information we were looking for, it gave us a good idea of how our unit should open up. With a bit of trial and error, we quickly managed to get all parts separated and fully inspect the components. It was surprising to see that most pieces were made of plastic, not metal as we had imagined, and the unit was so simple.

Nothing seemed damaged until we identified the electromagnetic clutch.

A quick inspection of this component confirmed the effects of the overheating situation. It was clear something had melted inside the clutch assembly.

At this point, there was nothing to lose, the pilot was broken, and beyond our repairing skills, so we continued disassembling, curious to see what was it that had melted inside the clutch unit.

Further inspection showed the glassing of the electromagnet had cracked in several places and that the main bearing had oozed some sort of lubricant. We also noted the central bearing was seized, likely due to heat damage.

We decided to test the electromagnet component.

Once again, using our portable 12v battery, we powered the electromagnet, and at first eye, it was working, it was “activating” the magnet when power was on.

(Identified by putting a metal tool close to the centre of the electromagnet, in this case, a screwdriver)

As per the advice of our great marine electrical adviser Graham, we performed a simple test where we would power the electromagnet for 10 seconds and then let it rest for another 10 seconds before repeating it throughout for a few minutes while checking how fast the unit was warming up. Despite not being fully assembled, the unit started heating reasonably fast, even without generating any movement (because it was not connected to the remaining unit, the centre bearing was not turning as it would in a normal situation)

The culprit was unequivocally identified.

The electromagnet was toasted! And the main bearing was seized.

During our disassembling process, we identified two numbers engraved on the clutch assembly, one on the electromagnet and the other on the main bearing.

Using Google, we quickly found a local supplier for the central bearing in Brazil at a surprisingly low price, we also discovered several suppliers for the electromagnet in Europe and that the actual manufacturer of that part was not Lewmar.

After a bit more research amongst all the European suppliers and we noticed strange enough none seemed to have the part in stock, and all mentioned several weeks for manufacture (thanks to Covid and all the crisis that has been hitting us ever since lots of products have run out of stock and production has not kept up). Thinking this was slightly strange we decided to search for the actual manufacturer and contact them directly to see if by chance they could supply us, bypassing the usual middleman.

Their reply was very simple, it would take them roughly six weeks for the production of our unit after confirmation of our order and payment, but yes, they could supply us directly, and they would even produce our unit not requiring a huge order. The price tag to repair our autopilot had gone from 4000+ Euros for a new matching unit, to a couple of thousand Euros for a new clutch assembly, to 600-800 Euros for a new electromagnet clutch (just the part we needed) via a third party supplier to shy of 400 Euros including shipment from the manufacturer directly.

The problem was still the lead time of production to which we needed also to add the time required to deal with customs because the manufacturer is in the UK, and we would need it to be shipped to Portugal in Europe (time and import expense to Brazil ), where we could have it received by family and then picked up by Ana on a quick (but expensive) flight home, all this while our visas clock was ticking in Brazil, a huge country that requires time to cross.

The bottom line, although possible this was not going to be the answer to our problem in the immediate moment.

We needed a working autopilot much sooner than the presented timeline.

Despite this long lead timeline we decided to have the new electromagnet manufactured and shipped to our family for a later repair (and this way, ensure we have yet another redundancy).

With the repair option off the table for the time being, we were back to the situation of pulling hairs out and trying to figure out what to do.

Should we buy a matching unit or should we go for a hydraulic pilot?

The answer was not so straightforward:

* there was a significant price difference between drive units (go figure, a drive unit is more expensive than a hydraulic unit in general), but it would be a direct swap without having to change anything else;

* a hydraulic unit seems to be stronger (or at least rated for a heavier boat, 20 tonnes vs 23 tonnes) and maybe more reliable, but installation space and specific arrangement dictate the suitability of each unit.

After checking several models and brands we concluded that to avoid having to install a new Course Computer we only had one hydraulic option and to avoid having to buy a new sprocket with a matching chain (smartly for the manufacturers and sadly for the buyers the different brands and models of drive units do not use the same size sprockets and chains forcing a complete replacement of the steering system) one drive unit option (a perfect match to our unit). With the options narrowed down to two, the above conundrum still applied.

In both cases, it seemed there were barely any units in stock available anywhere!

After much discussion, we decided to go with the hydraulic pilot because of the price difference and also because we felt that with a bit more wiggle room on the tonnage limits of its specifications, we would have a more suitable option for offshore sailing. The original pilot was on the upper limit of our boat size, meaning in offshore sailing it was probably working harder than desired and for longer than desired.

With that decision made now, the issue was who could guarantee delivery in a reasonable time in Portugal where we could receive it and then collect it?

The UK suppliers had a better price, but they would have to receive the unit from Raymarine UK (that had confirmed its existence in stock) first before they could dispatch it to us. But since Brexit, it has become troublesome getting things through customs, and this could mean 1 week for shipment within the UK, then another week to Portugal, then probably 1-2 weeks in Customs plus any days waiting for payments to be processed in between all parties, we could count easily with anything from 3 to 5 weeks. On the other hand, SVB in Europe had one unit left, slightly more expensive than the UK suppliers, but guaranteed delivery in 5 days, sometimes less.

When time is of the essence, sometimes we have to pay the price for a guaranteed delivery timeline, and so we did, the day after our exercise of disassembling the drive unit we ordered the new pilot. It was now the weekend and time to try and relax before starting the quest to buy a reasonable price flight to Portugal once we had seen the ordered part was in transit from Germany to Portugal.

***In the spirit of sharing our dreams and experiences we have shared this blog post in the NOFOREIGNLAND.COM website sailors community.

You may also use this tool: licenseplatelookup.org to get history of any car before making purchase.